A Letter from McTech Dental Lab Regarding PEEK Scan Bodies

In March of this year McTech Dental Lab distributed a letter to our doctors discussing the use of PEEK scanbodies and the flaws they can sometimes produce. This blog is a background and discussion around this letter, the cases that provoked it, and the subsequent research. To skip to a copy of this letter click here.

Preamble

Every month McTech conducts a remake meeting where a list of any and all remakes and adjustments are discussed and solutions for bettering ourselves are found as a team. It encourages us to collaborate and to think critically about what can go wrong and seek pragmatic solutions. For the facilitation of these meetings a list of remakes and adjustment cases is produced. The list gives each case a reason, includes notes recorded by the technician and essentially tells a story. Importantly, the list assign’s fault to us the lab, the doctor, or in some cases the patient.

What is most important for us during these meetings is getting to the why. The most frustrating outcome is when the why is a total mystery. Obviously, a lab never wants to accept this outcome for any remake, but we can only vigorously investigate our own processes and workflow.

My role is often to bring into the conversation the latest research on any topic of discussion. I look up mostly free white paper scholarly papers and will even consult dental lab forums or dentist forums for leads and resources.

If it becomes clear that we made no errors, and the remakes persist, we then need to involve the other parties of the restorative team. This can include manufacturer reps or support systems for the various technologies and materials we use.

Of course, a necessary party in investigating a mysterious remake or a series of mysterious remakes is our client doctors. We operate upon the belief that our doctors place the best interest of the patient above all other interests. Involving a doctor and their staff in a rigorous remake investigation, however, can easily ruffle the feathers of our very respected dental offices and at some point, any further investigation could be interpreted as an attempt to shift responsibility. We never play the blame game with our offices, and this helps to receive very honest and solution-oriented feedback from our doctors. Our entire philosophy of quality hinges on open communication drawing an intrinsic road map to the best possible case outcome. At a certain point a question eventually arises, in business terms, is the juice worth the squeeze? Fortunately, our experiences with communication and researching along side our dentist clients has been exemplary. That being said, there is certainly an alignment of financial motivation for every party involved in restorative dentistry to get a case right the first time. I know I can speak for most labs, and I will only assume doctors as well, when I say even a single full remake of a case essentially erases our profit margin for more than that case.

When considering making a recommendation on a given product, material, practice or technology we do our best to do so when it seems the most valuable. This includes Topics that fall within our purview and where there seems to be a lack of scientific consensus.

Throwing our two cents into a topic that is being rigorously discussed by learned professionals, research labs, and doctors all over country and world is not without it’s risks. We are a dental Lab and not a research lab. We catalog and investigate our remakes and adjustments and to the best of our ability we utilize our experience, technology, and tenacity to draw conclusions.

Sometimes our recommendations may conflict with what the latest studies or generally accepted practices have recommended. In which case we either reevaluate our recommendations or try to back them up with something more concrete than just our personal experience.

Background

Mark, McTech Dental Lab’s founder and head technician, has been a dental technician for over 40 years. He can recall the days of his career when he was first introduced to dental implants in the early 80’s. In those days the failure rate of implants was much higher, and the failure point was far more to do with osteointegration than anything the lab could control. Mark has seen many implant types and brands come into and go out of use; he has a great scope of the implant graveyard. Phillip Williams, our other senior technician started his career as a dental technician in 2000 and remembers the disaster that mini-implants presented when doctors were attempting to place fixed restorations on them. Both Phil and Mark bore witness to the evolution of implants into the successful restorative solution they are today. Evolution is not always a pretty thing to behold, manufacturers, and labs, and doctors all go through a learning curve even with the latest best, science available. It is no surprise to us to see that when a relatively new restoration, like the dental implant, meets an even newer modality of communication technology, like intra oral scanning, there is a learning curve.

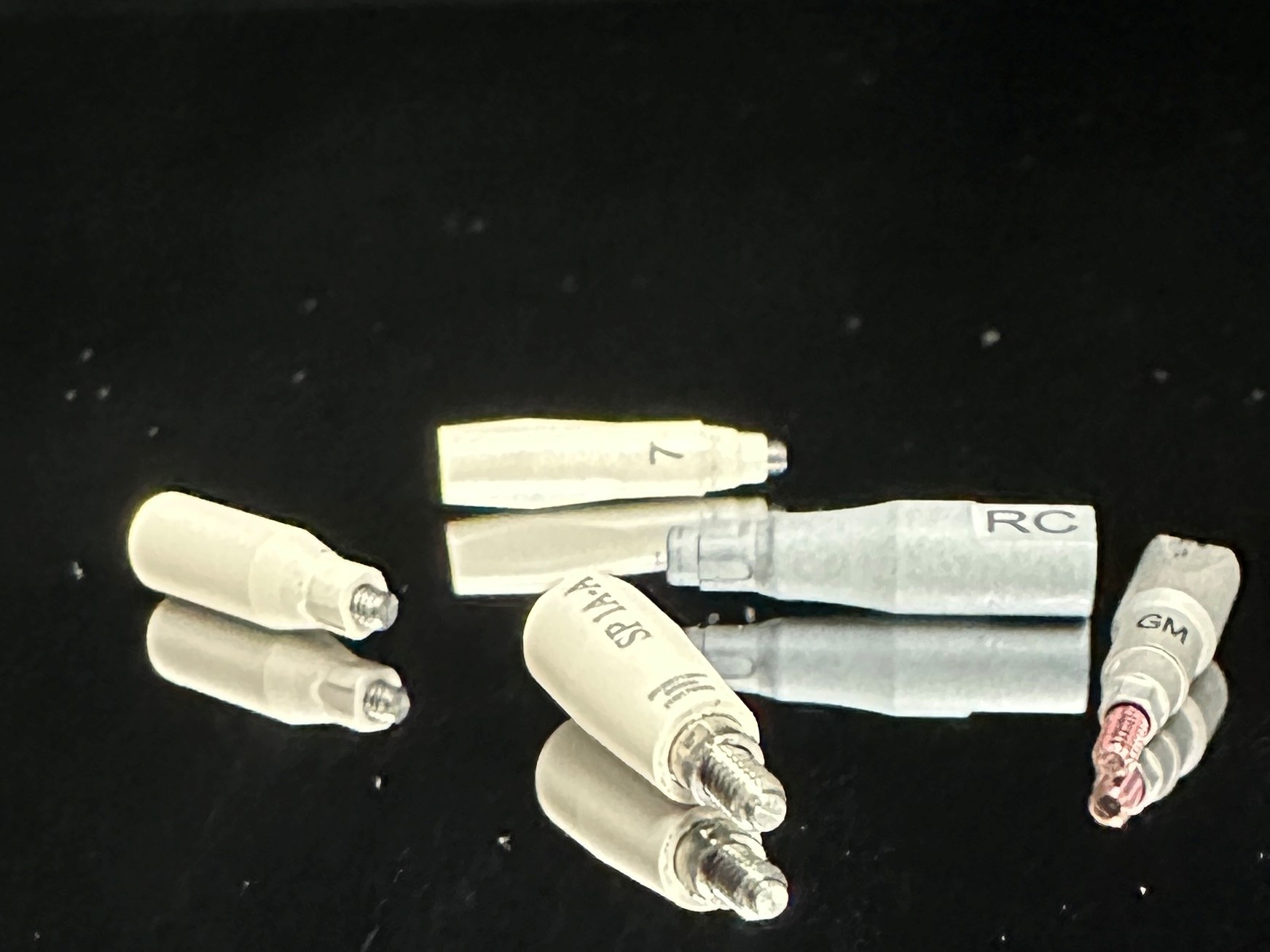

It was a bazar happenstance of 3 implant remake cases from the same doctor over the span of three months that started us down our investigation of intra-oral scan body material choice. All 3 of these cases were distorted in different ways. All three used different implant systems, Straumann, Neodent, and Neoss. At the seating attempt our doctor was able to confirm that a perfect fit was consistently manufactured to the 3D printed model. The doctor would rescan the patient and each time it was a guessing game as to if the new scan would produce a better result. In the end, and for each case, a physical PVS impression was needed to replicate the true position of the implant, after which only one of the three required a full remake and the other two could be adjusted. This fact alone raised a red flag that the source of the problem has to do with the digital aspects of the workflow.

Once the cases were successfully complete, we turned our attention to identifying and rectifying the problem. We started with things on our end, confirming the calibration, updates and maintenance of our CAD CAM equipment and software. We learned early on that no single point of failure in our workflow would account for the variety of variables in these three cases. Regardless, we set about eliminating any possibilities on our end hoping this wasn’t somehow a combination of process flaws or that by some freak of nature these cases had no common reason at all. We first had the idea it might be our CAD implant design module library. But everything was up to date, and we found no flaws. We next had the idea that it may be a flaw in our 3D printing. We eliminated this using our desktop scanner to confirm the accuracy of the print to the initial scan sent to the lab. In this way we vetted as much on our end as we could.

Next we turned to the doctors scanner. The doctor used iTero scanners, and coincidentally our technicians had previously received extensive training with these very platforms. We contacted iTero on the doctor’s behalf and learned from the tech support, that the doctor used three different iTero scanners in three different bays. Not all 3 cases used the same scanner. We also learned they had all been recently calibrated as well. Eventually we concluded the source of the error could not have been from the scanners.

Our possible options were eventually reduced to the scan body. We tried to get ahold of a representative from Neodent. That was when we discovered she had just left the company and a new rep was being trained. As far as neoss, we did not at this time have a close relationship with their sales representative. We didn’t even have their contact information and decided that pursuing Neoss may not be the best route at this point. This investigation was at this point carrying on longer than we hoped and all attempts at contacting were being made during lulls in production. John was able to have a brief phone conversation with the Straumann sales rep. The Straumann representative we spoke to was brand new, nice guy but he was only able to provide sparse insight. The sales rep gave no information or indication that there was a persistent or systemic issue with their scan bodies. We were left with the impression that In pursuit of that inquiry, we would need information about the scan body used in these cases such as the lot number of the scan body used.

We could have at this point contacted the doctor and asked if they had this information. Or we could have requested to borrow, and scan, the very same scan body that was used in these cases and compare it’s dimensional accuracy to a scan of a new scan body. When at all possible, we try not to let our remake investigation become a hinderance or nuisance to our clients who at this point have moved on. The clinical side of the issue demands we persist and discover a solution, but the business side questions “is the juice worth the squeeze”? It was decided that we should have more to bring before further inconveniencing our Client.

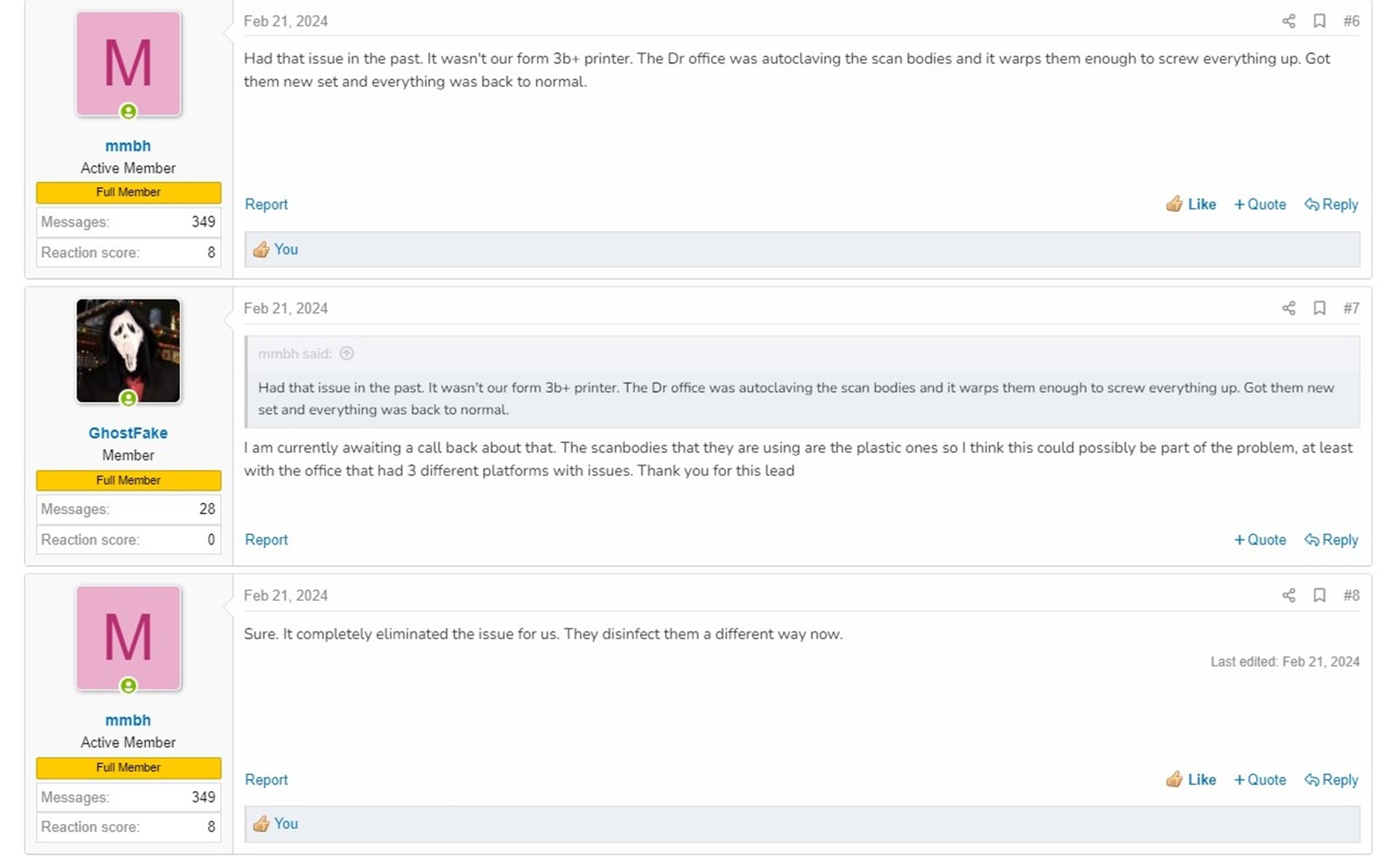

So, when traditional lines of inquiry go nowhere, we get non-traditional. From the very beginning of the investigation, we posed the question to one of the online dental lab forums. Because of the anonymous nature of these dental technician forums, they are a treasure trove of perspectives that are, if not always accurate, at least honest. It is a great place to confirm we are not the only lab experiencing any given issue and, in this case, generated exactly the lead we were looking for. Our head CAD CAM Technician, John, is seen here on this forum going by the name GhostFake….(I don’t know why). Another member hits on an exact reason right away, the plastic scan bodies the Dr.’s were using were warping due to being autoclaved.

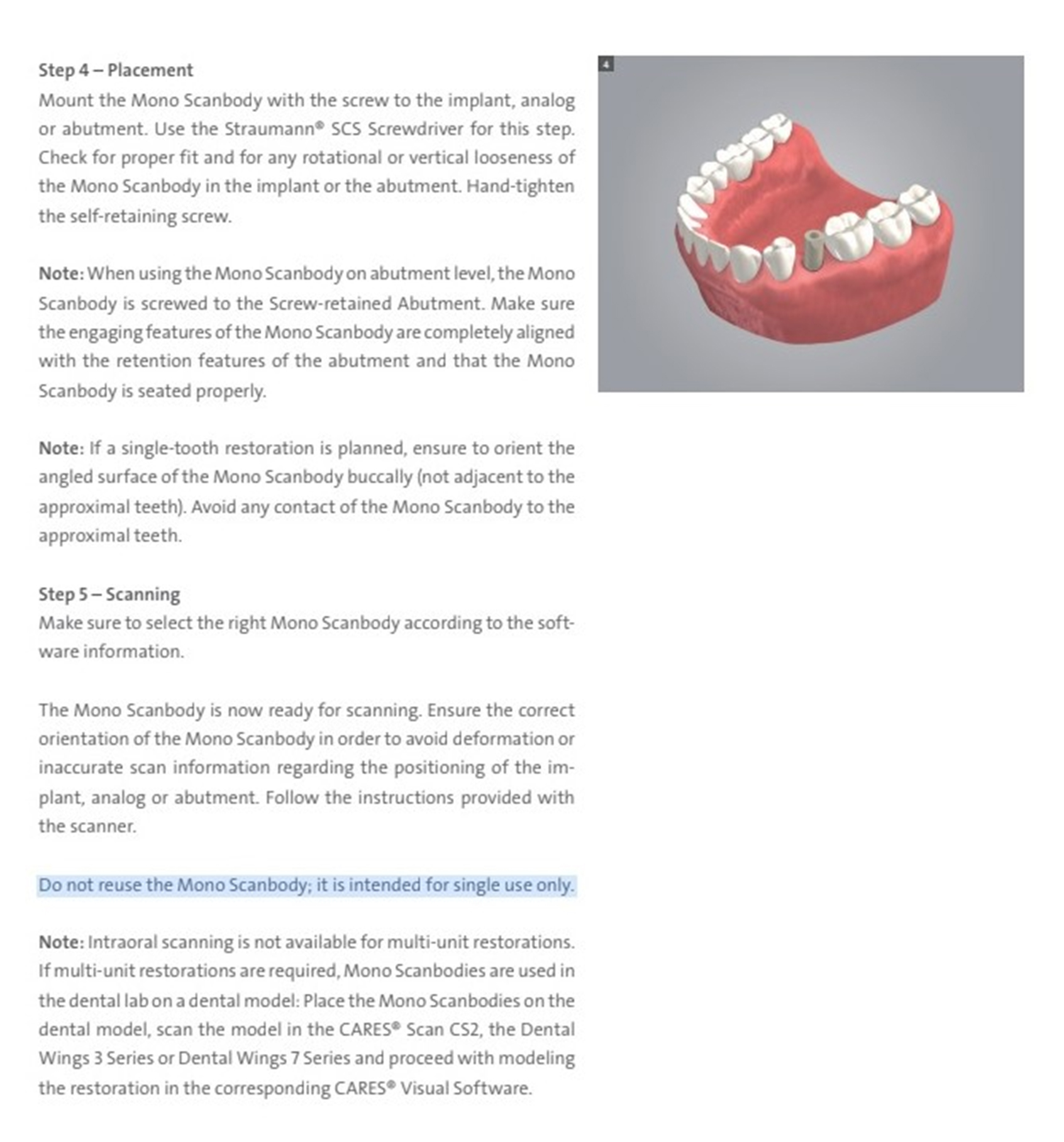

John obtained a copy of the Instructions for use for Straumann’s PEEK scan bodies(1). This was one of the implant systems used in the cases. Stated very plainly and separate from the rest of the text was “Do not reuse the Mono Scanbodies; it is intended for single use only”.

John then called Straumann to talk about what he had found and that is when he learned that Straumann was discontinuing their Straumann CARES Mono Scanbody made from PEEK and in their place were providing Titanium scanbodeis. It should be noted at this point that discontinuing an entire line of over a dozen products and reengineering them out of an entirely new material is not done on a whim. When he asked the representative why, he was told doctors were unhappy about the fact they were single use. John referenced his conversation with another lab on the online forum and asked the representative over the phone “have any of them been complaining about distortions?”, to which the response was “yeah that too”. As is often the case the manufacturers instructions for use are either not known to the doctor or they simply disregard them. However, it was unlike this particular doctor to do so. John then made a call to our client doctor and confirmed that indeed they had been using PEEK scan bodies and autoclaving them for multiple use. That they had been doing so for some time. We did not lean into our very valued doctor as to why, instead we just informed them that the scan bodies should be checked to see if they are recommended for single use. They promptly discarded all PEEK scanbodies and replaced them with a titanium version.

Scan Bodies warping fit the bill of these three cases to a tee. We looked back for any digital implant remake or adjustment cases involving timing, proximal contacts that were inexplicably far too tight and other times wide open, or, in the case of multi unit cases, bridges that did not achieve a passive fit that were also unexplained and could have been the result of scan body distortion. What we found came from different doctors, using various implant platforms, all using PEEK scanbodies. Some of these cases were screw retained, and some were cement retained. It did not matter what material we made the crown from or if it was designed in CAD like our zirconia or traditionally fabricated like our cement retained PFM. There honestly weren’t many, but in the back of our minds was the “iceberg” effect. This could be the cause of any number of past remake mysteries along with an unknowable number of “good enough” adjustments we never heard about.

Mark wasn’t entirely happy with our conclusion that autoclaving would account for the entirety of the issue we were seeing. He had no doubt that the scan bodies were the source of the issue but brought up a thought he had scratching at the back of his mind for some time. “Once I heard we had narrowed the cause to the scan body, I immediately thought about how over torquing those pieces of plastic could possibly cause them to rotate slightly with the screw on the last turn.”

So we have several questions now. Does autoclaving distort PEEK scan bodies? Does torquing distort PEEK scanbodies? How does Titanium compare to PEEK in these aspects? And why are Manufacturers preferring PEEK as a material for scan bodies over titanium? Titanium is a well known quantity in the oral environment and for the most part the same material as most of the other components in a given implant system.

To begin answering these questions I first consulted instruction manuals for various implant system manufacturers to see what information, case studies, or even instructions for use they would offer up. At this point we already learned that Straumann had done away with PEEK as a scan body material altogether and we wanted information as to why.

I attempted to visit the Straumann website but after too much time spent and too little to show I decided to switch tactics. A rudimentary scholarly article search revealed there was also a lack of consensus, and that it would take time to go that route.

Based on our case experience, what we found on forums, and what action Straumann was taking, we decided it was prudent to inform our doctors of our recommendations. The following is a copy of the letter that Mark and John penned, and this was either mailed or hand delivered to each of our accounts.

Our Letter

Intra-Oral Scanbodies

As of mid-February 2024, Straumann has discontinued their Cares PEEK intraoral scanbodies due to complaints about their single-use nature, as well as distortion in the scanbodies that have been sanitized using the autoclave resulting in restorations that did not fit upon seating of the implant crown. In its place, they have released Titanium Scanbodies that can be used around 100 times before they are to be replaced. We were made aware of this issue when we began experiencing some fitting issues on multiple platforms that also have or had PEEK scanbodies. We then found out about other labs that had run into the same issue and had determined it was because the scanbodies had been disinfected using the autoclave. We ran several tests on our manufacturing process’ which all ultimately led back to the scanbodies being distorted in some way. Both Straumann and Neodent offer a titanium altearnative, and Elos has scanbodies that have a PEEK scanbody with a Titanium engaging option to replace the brands that exclusively use Elos to provide their digital products (Neoss, Astra, Nobel, Etc)

Straumann Titanium Scanbodies-$59 Neodent - $45 Elos - $75

We recommend that all PEEK scanbodies be replaced with solid titanium scanbodies. If a solid titanium option is not available, please use scanbodies that have a titanium engaging portion. If any portion of the scanbody is PEEK material, DO NOT autoclave. If a PEEK scanbody must be used, it is recommended for one time use only.

As dentistry continues down the digital path, we will continue to stay up-to-date on the most current trends and techniques. We will also continue to do our own research and development in order to maintain our expectation of producing the highest quality products.

Thank you for your continued patronage. And please contact us with any questions or concerns.

-Mark McKee, CDT, & John Ingram, McTech Dental Lab

Building and Backing up our Recommendations

In pursuit of providing quality recommendations that promote case success for our patients, I first affirmed what McTech Dental Lab collectively already knows and what it assumes. PEEK has much lower light reflectivity than titanium. We know this because we have been using Scan bodies in the lab for over 10 years. Even titanium that has been surface treated for lower reflectivity could not match PEEK when it came to ease of scanning. As with all aspects of CAD CAM in our industry things change quickly. Advancements in the scan-ability of titanium have been noticeable and John Ingram, McTechs CAD/CAM technician of 10 years, attributes this to the advances in scanning technology. “With our previous benchtop scanner you could certainly notice the difference in PEEK vs. titanium scan bodies. It wasn’t often but sometimes I would need to dust the titanium ones if I wanted to get the crisp details I got from a PEEK scan body every time.” Since then, McTech has upgraded our scanner. John added, “with our new scanner, I never dust, and I can no longer tell, just by looking at the scan if the scan body was made from PEEK or titanium”

This gets into the reasons why manufacturers may prefer to make scan bodies from PEEK rather than titanium.

Reason 1: As we have just covered, PEEK provides improved scan ability. It is my opinion that this is the most acceptable reason a manufacturer would prefer one time use PEEK over a multiple use all- titanium alternative.

Other reasons are purely speculative. I do not single out any one manufacturer as I lay out these possible incentives. Most of these other reasons do not necessitate a ground for ethical ambiguity and can even be understandable parts of operating any manufacturing business.

Reason 2: Cost of PEEK production vs. titanium. As a dental lab with experience milling titanium, we are all too familiar with the machining costs involved. However, if PEEK cannot prove to consistently perform after many iterations of use and sterilization, it could quickly cost more.

Reason 3: Speed to market. Again, this is speculative, but rolling out a product that is declared to work once is likely executed far faster than the time that it would take to determine appropriate guideline for reusing the same product. Research and development cost for medical devices like implants is a notorious money and time pit, especially when the FDA is involved.

Reason 4: limiting liability. Declaring that their scan bodies are accurate only once is a more defensible claim than the claim it is accurate twice, or multiple times for that matter. From a legal department perspective, to achieve the least amount of liability, only approve for one time use, and make no other promises. Referring to an implant systems disclaimer of liability makes this clear.

Reason 5: Consumable Profit model: As a business graduate and small business manager, I suppose I am as qualified as anyone to speak on this and I know, as fellow small business owners, many of my client doctors have a similar background. Obviously creating a scan body that must be purchased over and over for each patient is going to generate continuing sales.

Manufacturer IFU Review

In continuing pursuit of providing quality recommendations that promote case success for our patients, I gathered and reviewed the instructions for use from various major implant part manufacturer websites. I also considered any other literature that manufacturers made available. I first focused on the companies involved in the 3 original cases. Straumann, Neodent, and Neoss. For good measure I also included Nobel and Elos. I looked for the most up to date versions for all 5.

It would make sense to include Straumann and Neodent together for a moment since they are both a part of the wider Straumann Group. Both lines of scan bodies were of an all-PEEK construction, with no titanium. Both clearly state these scan bodies are for single use twice or more and Straumann even states it twice in two sentences(1)(3). Both mention hand tightening as permissible but interestingly Neodent in parenthesis states “(maximin torque of 10Ncm)”. In my opinion this is a contradiction of recommendations. To Neodents credit, they have the only IFU that includes in its PRECAUTION section a list of what is at risk if the product is reused. “changes in physical, mechanical and chemical properties of products, macro and micro structural, that can put at risk the desired functionality. The reuse of this product does not guarantee its safety and efficacy and disclaims any warranty of products.” In January this year both companies rolled out all-titanium alternatives that now allow for 100 reuses. Both approved the use of hand tightening though Neodent still states “with a maximin torque of 10Ncm”.

After reviewing the documents, I called representatives from both companies for further insight. For Straumann I got ahold of Jennifer Brend, our former sales rep from years ago. She is a bit of a legend around here; one could easily credit her for the market share that Straumann now enjoys in Billings MT. According to her new email handle, she is now the executive territory manager for the Dakotas. She really knows her stuff so I knew she would be the best to talk to. She informed me that the reason for the switch to titanium was popular demand. She pointed out that PEEK cannot be seen on an x-ray and now with titanium we can image for confirmation of seating. She recommends doing so to all her doctors because it is a very common-sense protocol that improves the odds of case success. She told me the new titanium scanbody has a proprietary coating that helps to reduce reflectivity and rounded edges near the taper also reduce reflectivity. The labeling on the scanning portion has improved as well, something our CAD CAM technician, John, loved hearing. Jennifer told me she had been with the company for a little over a decade and in that time she counts this new design as the third generation. She told me Straumann has never recommended the previous PEEK designs for multiple use. She understands why a doctor might want to, but does not know where doctors may have gotten the idea it was ok to do so. As far as torque, she has always told her doctors to use 15 Ncm, even though the instructions approve hand tightening. She said hand tightening typically produces around 15Ncm anyway (something that I found research for to corroborate (11)) but also it just makes things simpler. The torque wrenches Straumann provides has two settings, one at 35 Ncm for the final restoration and one at 15Ncm for just about everything else. The final feature worth mentioning is that the scan body is designed such that the screw cannot engage the threads unless it is seated all the way down. She has told her doctors the dangers to their warranty should they use third party components and that the x-ray imaging confirm seating should always be sent to the lab. Before hanging up she hinted at a new scannable PEEK healing abutment soon to be released. On their website, the PEEK Scanbodies were no longer available for purchase.

For Neodent, I got ahold of a knowledgeable tech named James and he told me much of what Jennifer told me but rather than simply popular demand, he admitted that doctors reusing the PEEK scanbody was a problem. He told me the Neodent torque wrench allows for 10, 15, and 32 Ncm and recommends to his doctors they do either 10 or 15 Ncm when torquing a scanbody. On their website the PEEK version was still available for some platforms but it is no longer being made.

Both IFU mention that inspection of the scan bodies for damage or warping was mandatory before the first use and before each reuse.

I reviewed the Neoss IFU and literature(5)(6) for their scanbody and discovered it was of the hybrid design that included both titanium at the base and PEEK at the scanning portion. The literature states that inspection of the scan bodies for damage or warping was mandatory before use. There is a liability statement warning against 3rd party components. The IFU says the attachment of the impression coping and the scan body is made by hand tightening however there is a table present on the next page saying the impression coping is to receive 10 Ncm Max. Neoss is vague about the scan body reuse in it’s IFU but gives me enough referencing of other document to chase down the conclusion that it is not a multi use product. It is not entirely clear if this is a reusable component or not. In the IFU INTEDED USE section, I found the statement “Abutments and Impression products (except for TiBase Impression) are intended for single use for a single patient.” I could not find a document that contained a list of items considered an impression product, however In the cleaning instruction document there is a very detailed list of reusable items of which the PEEK scan body is not listed. What you will easily find referenced on the Neoss website and present in all the literature is an abundance of information regarding its new scanning peg made from PMMA. This is inserted into a PEEK healing abutment, scanned, and then discarded.

I decided to review the literature provided by Nobel for their scanbody because of the national market share they currently hold(7). In our area, we don’t see as much Nobel, and the few times we have see a scan it was a 3rd party scanbody used. Either Nobel never had one that was made from PEEK or at some point they did away with it because any literature on it could not be found in my dive on their website. There was plenty of information on their new design however. The new design is made of titanium with a Zirconium Nitrate coating over the scanning portion. In the IFU they say it is reusable up to 100 times, similar to the new Straumann and Neodent lifetime. Also is the instruction to hand tighten but caution against over tightening. They also ask to confirm seating using x-ray imaging.

I decided we needed to include at least one 3rd Party manufacturer so I decided to dive into the one our doctors have us dealing with most often, Elos(8)(9). Elos has followed the new trend as well and completely revamped their scan bodies. The newest iteration is composed of the all-titanium design now in favor. Some of the other features listed on the factsheet available from their website include x-ray visibility, improved labeling, a surface treatment that makes it more scannable, and reusable up to 100 times. Notably, they mention it is unaffected by temperature fluctuations, insinuating this was and possibly still is a problem for other designs or materials. This change must be very recent because they still only made available an IFU that is for their previous 2 piece PEEK design. This is the first PEEK scan body IFU that I have found that states it is for multiple uses. For sterilization procedure they simply state it can be cleaned according to MDR (Medical Device Regulations). They make similar statements about handling with care and inspecting before use for cleanliness and damage. When discussing torque, “Hand-torque the scan body until stable – No more than 5Ncm.” This is similar to the contradiction I found on the Neodent IFU. It does not state how you be sure you don’t over torque without a torque wrench. A similar contradiction appears on the fact sheet available for their new Titanium design where in one section when discussing correct handling in parenthesis “(hand tighten only)”, and in the last section when discussing reducing the risk of errors also in parenthesis is “(max torque is 5Ncm). This is easily the lowest torque recommendation I have come across, especially for a titanium design.

Overall, most implant manufacturers IFU that I reviewed state that their scan bodies were either one time use or multiple use at appropriate points in their instructions for use or some other literature. All name brand manufacturers state clearly at one point or another the liability risks of using third part components. Most have done what Straumann has done and moved away from PEEK as a scan body material in their latest iteration.

Important are the inferences made about scanbody distortion due to autoclaving throughout all the reviewed implant manufacturers reviewed literature. This was either expressly or heavily implied repeatedly and was such an issue It could have been a major factor in the trend we see all implant companies participating in to move away from PEEK as a scan body material in favor of either incorporating the healing abutment in some way or using coated titanium.

Another heavily insinuated factor was the use of torque. Most gave maximum torque or at least warned against overtightening though none mentioned the consequences.

Scholarly Research Review

In continuing pursuit of providing quality recommendations that promote case success for our patients, I conducted an online query on PubMed Central for scholarly articles pertaining to the distortion of scan bodies. For full disclosure, the articles selected were first and foremost free. The benefit of this bias is that these articles are available for free download to anyone reading. Other than this bias, all articles were chosen based on their relevance, the date published, and meeting certain criteria such as peer review and a declaration of no conflicts of interest.

When we first wrote our recommendation letter, Mark wanted to personally hand it to most of our doctors. Based on the reactions, the reusability of PEEK scan bodies was a popular misconception. I turned to what the research community has discovered on the topic and what I found was that bad advice was hardly the only source of the problem. I did a search on PubMed and read from front to back eight studies and most turned out to have either severely limited scope or were revealed to be pilot studies. Most also admitted this in their conclusion and articulated a call for further studies.

I won’t discuss in detail all eight, but one study I decided was worth covering in more detail led me to believe I had found a possible lead as to why doctors were under the impression that a PEEK scan body would be reusable despite what the manufacturer recommended. The study was Published in November of 2022 and titled “Effects of Autoclave Sterilization and Multiple Use on Implant Scanbody Deformation In Vitro” by Takamitsu Kato et al(10). Taking from the intro, Kato et al made statements supporting McTech’s understanding as to why titanium would be desirable but has drawbacks. “The merit of titanium SBs(scan bodies) is that titanium is strong material, it can be used many times, and it is autoclavable. However, as it is metal, it reflects light, which makes it difficult to scan intraorally”. Kato et al then cite a previous study in support, however no statement was made regarding if this has changed with the advancement of scanning technology or an improvement of the surface treatment or coating used on Titanium scanbodies.

Kato et al acknowledges they are conducting a study that is going against the manufacturer recommendations “In order to prevent any potential deformation, SBs made of PEEK are recommended for single use.” They add “As PEEK scan bodies are recommended for a single use, no reports have been published regarding their sterilization.” I feel the authors then make a statement that alludes to my previously mentioned reasons 2 through 5 for why a manufacturer would favor PEEK over Titanium. They continue “In the medical field, disposable products are commonly used. Sometimes, this is not only because of the need for aseptic treatment, but because the cost in terms of human resources to clean the device is greater than the cost of using disposable products. However, for a sustainable society, developing a system that enables reuse whenever possible is essential. In that context, it is important to clarify the possibility of the multiple use of PEEK SBs.” At the end of the introduction, Kato et al states “The purpose of this study was to evaluate the effect of repeated torquing, sterilization and combination of both on the accuracy of PEEK tissue and bone level SBs.”

The following is copied from the conclusion that Kato et al comes to. “In this study, autoclave treatment had some effect on the deformation of the SBs. On the other hand, repeated connection and disconnection of the SBs under the torque of 15 Ncm did not show significant difference. The combined effect of repeated autoclave and connection-disconnection did not show significant difference. From the point of clinical application, the reuse of PEEK SB can be considered under proper sterilization protocol. “

The conclusion of this study implies without explicitly saying so that the manufacturers recommendation could be ignored. Never discussed in the study was the consequences of liability, should a clinician choose to do so.

In my opinion the study seems to have attempted to draw too wide of a conclusion with too small of a sample size and too few iterations of use for the variables uncovered. To accomplish the stated purpose, the iterations should have continued until all groups were observed to exhibit a clinically significant difference. Because no reason for the number of iterations was given the following should have been added to the stated purpose of the study to prevent misleading conclusions.

“The purpose of this study was to evaluate the effect of ten repeated torquing, sterilization and combination of both on the accuracy of PEEK tissue and bone level SBs.”

I reviewed this study in detail for two reasons. First, it was one of the available studies I could find that made such a strong conclusion in favor of PEEK scanbody reuse without qualifying statements that it’s scope was limited and calling for further investigation. The other reason is because the scan bodies used in this study were none other than Straumann CARES Mono Scanbody made from PEEK. So here we have a study that directly contradicts our real-life experiences with the one of the very same line of scan bodies that started this investigation for McTech Dental lab. When forming our recommendations, We want to see what kind of science has been conducted, rather than simply state the obvious about following manufacturers recommendations.

I did not ask Straumann to comment on the conclusions of this study. However, discontinuing and reengineering of an entire product line to a previously favored material is a strong statement.

To answer Marks original hunch that the act of tightening the screw of a scan body could overtime or with enough overtightening distort the scan body, I found a study published by The Journal of Advanced Prosthodontics in June of 2020 titled “Displacement of scan body during screw tightening: A comparative in-vitro study.” by JungHan Kim et al(11). It compared the effects of applying 5Ncm, 10Ncm and hand tightening. Kim et al determines in the Materials and Methods section that hand tightening constituted 15.7 +/- 1.3 Ncm by conducting an experiment with 4 dental students, and cites another study with similar results. Kim et al also conducted pilot studies to determine the sample sizes for the multiple groups that consisted of multiple brands. At the end of the introduction, the stated purpose of the study was “to evaluate the occurrence of vertical, horizontal, and 3D displacements during screw tightening of four different scan bodies, selected according to the material type (PEEK and titanium material), tightened to implant fixtures with tightening torques of 5 Ncm, 10 Ncm, and a hand tightening torque. The null hypothesis of this study is that there would be no difference in the displacement according to the types of scan bodies and tightening torques. amounts of torque on 3D, vertical and horizontal displacement.”

I covered this study in detail because it was more focused and included a larger sample of scanbodies with more iterations than many of the other studies I had found. Interestingly, Straumann CARES Mono Scanbody made from PEEK was used in one of the groups of this study. This was the very same scan body used for the remake cases that started this entire inquiry. One interesting conclusion in this study is that out of all groups of PEEK scan bodies, the Straumann CARES Mono Scanbody showed the least amount of transformation, though not as little as the titanium group. The results conclusively showed that Titanium was the superior performer in withstanding distortion from torquing. It was interesting to find that titanium was found to deform at all.

The recommendation in the conclusion was that only 5Ncm of torque should be applied to the tightening of scan bodies and it recommended against hand tightening, regardless of the fact hand tightening was determined to constitute only an average of 15Ncm. Of the IFUs from the manufacturers I reviewed, only Elos agrees with this. Others range in their instructions between 10 or 15Ncm as a maximum. Nobel at least acknowledges the care to be placed not to overtighten though it did not define it.

Despite what the manufacturer instructions say, the authors of the study corroborate what Mark also notes, that when it comes to muti unit cases, torque value should be consistent across the arch. Mark stated it is easy enough for a doctor to determine what their average hand torque may be. However, hand tightening will produce an unnecessary variable, and may conjecturally serve to cause one scan body to seat lower into the implant body than another on the same arch, causing incongruencies in the vertical dimension that would compromise a passive fit.

Our Recommendations regarding scan bodies

All literature found concluded that there is some degree of distortion as a result of autoclave sterilization in PEEK scan bodies. Conclusions also agreed that the amount of torque applied also causes some degree of distortion for both PEEK and Titanium scan bodies. Present in many articles was a statement along the lines that all variables regarding reuse should be considered and accumulatively. Also mentioned in some articles is the fact that multiple unit abutments compound everything by the number of implants and even slight variations in each would constitute a compromise to the passive fit or possible failure of the final restoration. The question seems not to be, is there distortion, but…

- At what point does clinically relevant distortion occur?

- How many reuses can be safely assumed?

- Does the number of reuses, safely assumed, change in a multi-unit case?

- At what torque can I safely secure scan bodies regardless of design?

Averaging all these variables into a few rules of thumb is a real challenge. If you are a dentist frustrated by the lack of consensus among peers and research communities, frustrated by a lack of guidance from the manufacturers, and want to consult with a dental lab on what they have seen and what they recommend, the following are McTech Dental Labs recommendations.

Recommendation on Material – Choose Titanium

Whenever possible, choose all-titanium for a scan body material. Only if reflectivity becomes an issue should you dust with powder or switch to a PEEK onetime use alternative. Do not surface treat or sandblast the titanium scan body without explicit approval and detailed instruction from the manufacturer.

If using a scan body designated as one time use, do not reuse. If the manufacturer does not make a clear statement about its reusability, assume it is not reusable.

Recommendation on Torque

Do not hand tighten. From what we have experienced and investigated, hand tightening can produce forces that at worst distort and compromise the passive fit of final restoration or at best, shorten the reusability of the scan bodies designated by the manufacturer as such.

Even for all titanium scan bodies that approve hand tightening, McTech recommends, instead, using a torque wrench to apply 10Ncm along with an x-ray confirming proper seating.

If the torque wrench provided by the manufacturer does read to 10 Ncm use the lowest available not to exceed 15 Ncm along with an x-ray confirming proper seating.

If manufacturer recommendations indicate less than 10Ncm, this supersedes our recommendations, however, an x-ray confirming proper seating is required regardless of manufacturers omission of this step.

Thanks for reading!

As concluding remarks, I want to state that the advances made in intra oral scanning for implant cases are a huge step forward. For all that we have discussed here, McTech can confidently say that this method stands to be more accurate than traditional methods. As is the danger of technology advancing faster than it’s users, It is important that manufacturers produce clear guidelines and that when called upon they also produce the necessary science to back up these guidelines.

There should also be a method developed for a doctor or lab to scan and compare at any time the dimensional stability of an individual scan body using itself as the initial baseline after unpackaging. That would put all this to rest.

References

- Straumann USA, LLC. (2018, May). Step-by-step instructions on the intraoral scanbodies. NAMLIT.1187 5/18 V1 PMR ifu.straumann.com Retrieved February 2024, from https://www.straumann.com: www.straumann.com/content/dam/media-center/straumann/en-us/documents/brochure/product-information/NAMLIT.1187.Intaoral.Scanbodies.Brochure.pdf

- Straumann USA, LLC. (2024, January). Basic Information Straumann Scanbody Technical handling iinformation NAMLIT.1658 1/24 V1 PMR ifu.straumann.com Retrieved March 2024, from https://www.straumann.com/content/dam/media-center/straumann/en-us/documents/brochure/product-information/NAMLIT.1658-Metal-Scanbody-Basic-Information.pdf

- Straumann USA, LLC. (2023). Neodent PEEK Intraoral Scanbody 330.306.06 ifu.neodent.com Retrieved March 2024, from https://ifu.neodent.com.br/Neodent/US/NEO?keycode=7899878022398

- Straumann USA, LLC. (2023). Neodent Titanium Scanbody 704759.02 ifu.neodent.com Retrieved March 2024, from https://ifu.neodent.com.br/Neodent/US/NEO?keycode=7899878056515

- Neoss Inc (2024, April) Permanent and Provisional Abutments and prosthetic accessories Instructions for use. 16392_1 2024-04 Retrieved March 2024 from https://eifu.neoss.com/neoss/US/IFU?keycode=Permanent+Provisional+Abutments+accessories

- Neoss Inc (2024, April) Neoss Instruments for Multiple and Single Use Instructions for use. 16443_1 2024-04 Retrieved March 2024 from https://eifu.neoss.com/neoss/US/IFU?keycode=Neoss+Instrument+for+multiple+and+single+use

- Nobel Biocare USA, LLC (2024, May) Position Locator Instructions For Use IFU1091 016 01 Retrieved June 2024 from https://store.nobelbiocare.com/us/en/eifu/instruction/search/?agreement_locale=en_US&agreement_country=&confirm-eifu=dental

- Elos Medtech Elos Accurate Scan Body Step By Step Installation Instructions 021.409_rev1

Retrieved June 2024 from https://elosmedtech.com/dental-professionals/dental-guides/ - Elos Medtech Elos Accurate ScanBody22 Factsheet 021.337_ver1

Retrieved June 2024 from https://elosmedtech.com/dental-professionals/dental-guides/ - Kato, T., Yasunami, N., Furuhashi, A., Sanda, K., & Ayukawa, Y. (2022). Effects of Autoclave Sterilization and Multiple Use on Implant Scanbody Deformation In Vitro. Materials (Basel, Switzerland), 15(21), 7717. https://doi.org/10.3390/ma15217717

Reterieved October 28 2024 from https://pmc.ncbi.nlm.nih.gov/articles/PMC9655283/ - Kim, J., Son, K., & Lee, K. B. (2020). Displacement of scan body during screw tightening: A comparative in vitro study. The journal of advanced prosthodontics, 12(5), 307–315. https://doi.org/10.4047/jap.2020.12.5.307