Modus Operandi Part 2: Wax On or Wax Off?

Underneath the McTech Dental Lab logo, one will find a summation of our value proposition, Bridging Technology and Artistry. Throughout the blogs, case studies, and marketing literature that McTech puts out, a reader can find various renditions of this statement in one form or another, but the basic message is the same. We are claiming to integrate the latest, best technologies and research with tried-and-true artistic methodologies. We are not putting artistry or technology on a pedestal. We believe dental technicians are not simply artists who build little tooth monuments unto ourselves. We men and women in the dental restorative field also need to remember that technology is being SOLD to us and advancement in technology does not presume advancement in dentistry. If we as an industry adapt to the wrong technology or adapt incorrectly to the right technology, it could put us years behind where we should be and where our patients deserve while contributing to the rising cost of dentistry

The purpose of this blog is to inform the reader of some ways that McTech incorporates a mix of cutting-edge technology and artistic tradition into our production workflow. As we evaluate the methods we use, we are first answering the question “Does this way or that way of making a crown make the crown better or worse?”. Only after we answer this question can we ask “To what degree is it clinically relevant?”. To fairly evaluate what CAD CAM has truly advanced, we will remember that strengths can be tied to weaknesses and look for “double-edged swords”. This blog is speaking from a fixed dental restorative point of view and does not mince words belaboring terminology. Our goal is to elevate the understanding of a learned audience, our doctors.

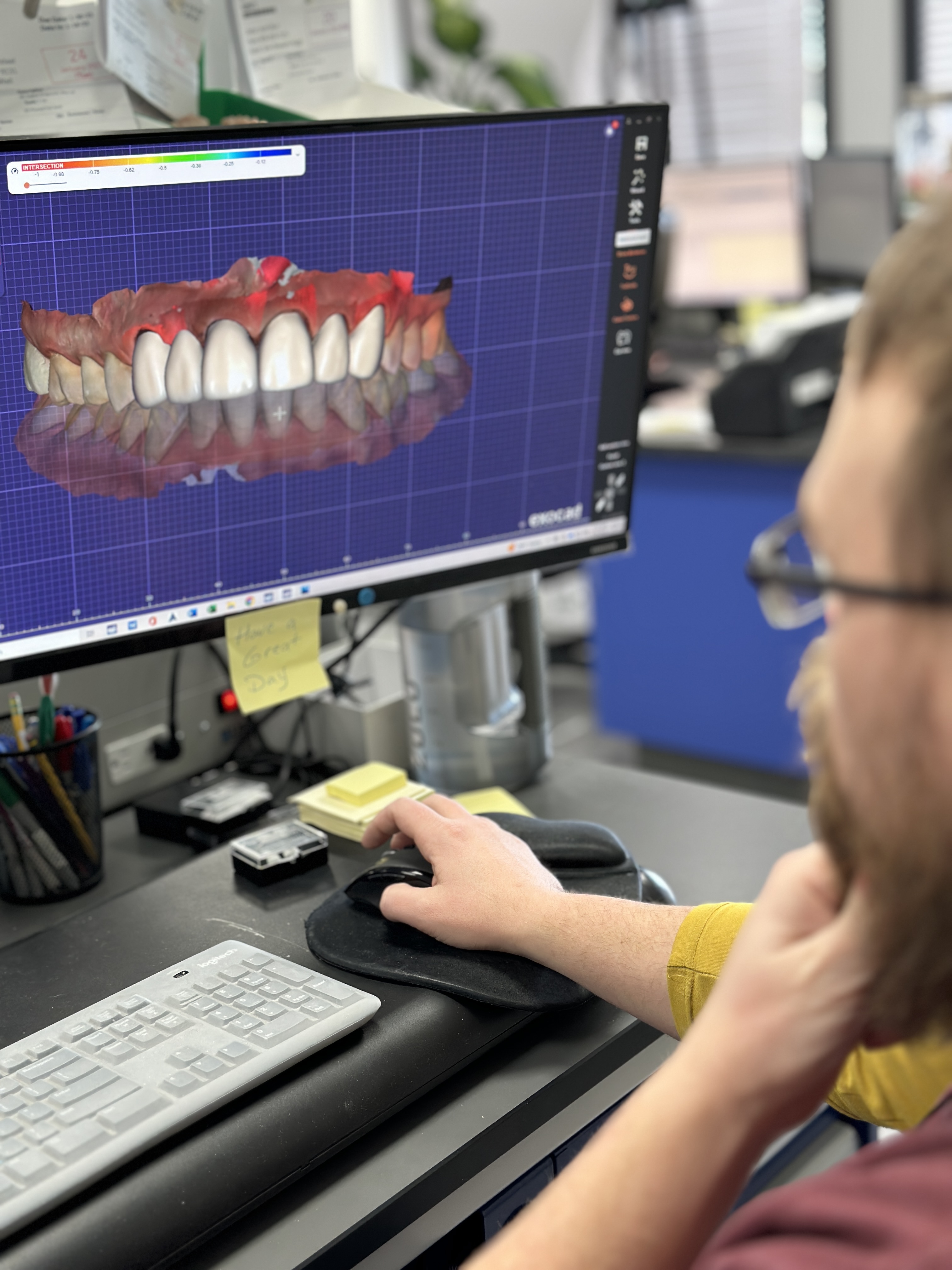

The first half of CAD CAM, Computer-Aided Design, should be discussed first. One of the things that CAD brought to fixed restorations, in any real sense, is an advancement in the use of tooth design libraries. These are a far cry from the silicone molds of the bygone era. By using libraries programed into the design software (in our case exocad) the designs we choose for various cases can achieve a consistent standard. While consistency is an important facet of a high-quality product it is not the only or even the most important facet. These libraries can come from world renowned technicians, can be customized, can incorporate different schools of occlusal theory, and satisfy aesthetic attributes such as feminine, masculine, young, old, square, oval, etc. The choices are literally endless, so the other edge of the sword, of course, is in selecting which library to use. On the fixed side, most of the time one of only a few libraries is used and then morphed to fit the situation. Aesthetically this can put the work a technician puts out into a very narrow box. The artistic standard for restorative work to mimic nature and individualize has always been high and should not be sacrificed for the sake of consistency.

The first half of CAD CAM, Computer-Aided Design, should be discussed first. One of the things that CAD brought to fixed restorations, in any real sense, is an advancement in the use of tooth design libraries. These are a far cry from the silicone molds of the bygone era. By using libraries programed into the design software (in our case exocad) the designs we choose for various cases can achieve a consistent standard. While consistency is an important facet of a high-quality product it is not the only or even the most important facet. These libraries can come from world renowned technicians, can be customized, can incorporate different schools of occlusal theory, and satisfy aesthetic attributes such as feminine, masculine, young, old, square, oval, etc. The choices are literally endless, so the other edge of the sword, of course, is in selecting which library to use. On the fixed side, most of the time one of only a few libraries is used and then morphed to fit the situation. Aesthetically this can put the work a technician puts out into a very narrow box. The artistic standard for restorative work to mimic nature and individualize has always been high and should not be sacrificed for the sake of consistency.

However, this is not a challenge exclusive to the use of tooth libraries, Mark can sometimes identify his old crowns from a stone cast, a reminder to him that every artist has their own styles.

An important capability of CAD in addition to tooth libraries is its ability to create a perfect replica of the previous dentition or a perfect inverted replica of adjacent dentition. Copying assumes that the previous dentition had nothing wrong with it, if so, a pre-op scan can truly take out all the guess work. However, if the crown or set of crowns is establishing a better bite, perhaps to address TMJ or to fix a crossbite, copying may be at best a great starting point. Mirroring can be a great advantage over hand-waxed crowns especially when designing centrals but the other edge of the sword here is that nature is never perfectly symmetrical and achieving this standard can sometimes only serve to produce vaguely unnatural aesthetics. And again, if the restorative team are attempting to improve the current situation mirroring best serves as a great starting point.

Unarguably, designing crowns, bridges, and implants on CAD yields much faster results. The process of training a technician to hand wax a single posterior crown that is acceptable can take weeks or even months depending on the technician. The time it takes to become fast can be years. Conversely, and especially with the advent of AI, so much of the process is automated that less and less knowledge or skill is being required of the operator. However, this is not the case at all for metal frameworks, which can be hand waxed far faster and with better results. Even with full  contour restorations, Mark McKee CDT, McTechs founder and head technician can give this technology a real run for its money. Especially if both are starting with stone model work, Mark can hand wax a posterior crown and have it casting or pressing before the mill is done. So what? What else does that crown mark made have over the CAD designed version? In a word, intimacy. We still train our technicians through the PTC hand wax module, if for no other reason than it gives them an intimate relationship with teeth, with the anatomy, with every cusp and ridge and faucae, along with the various ways a bite is functioning or not functioning. Mark can in the middle of waxing his crown realize through tactile feel and experience that the model room may have missed the bite slightly; he knows what occlusal anomalies to look for that can throw things off. Mark has the experience and expertise to think critically when working with the information given and does not just assume it is correct. Technicians born and raised in CAD, and yes even AI, are handicapped when it comes to these and many other functions. This means even the most straightforward case can suffer from operator ineptitude and the most advanced AI in the world can still only work with the information given. Complex jaw movements like those seen when speaking or dynamic mastication movements rarely if ever make it into the design of a sole CAD CAM restoration, even one made by a seasoned technician. While it is easy enough to add vertical space between teeth and even use a virtual articulator to estimate the final positions, it still requires at the very least a physical

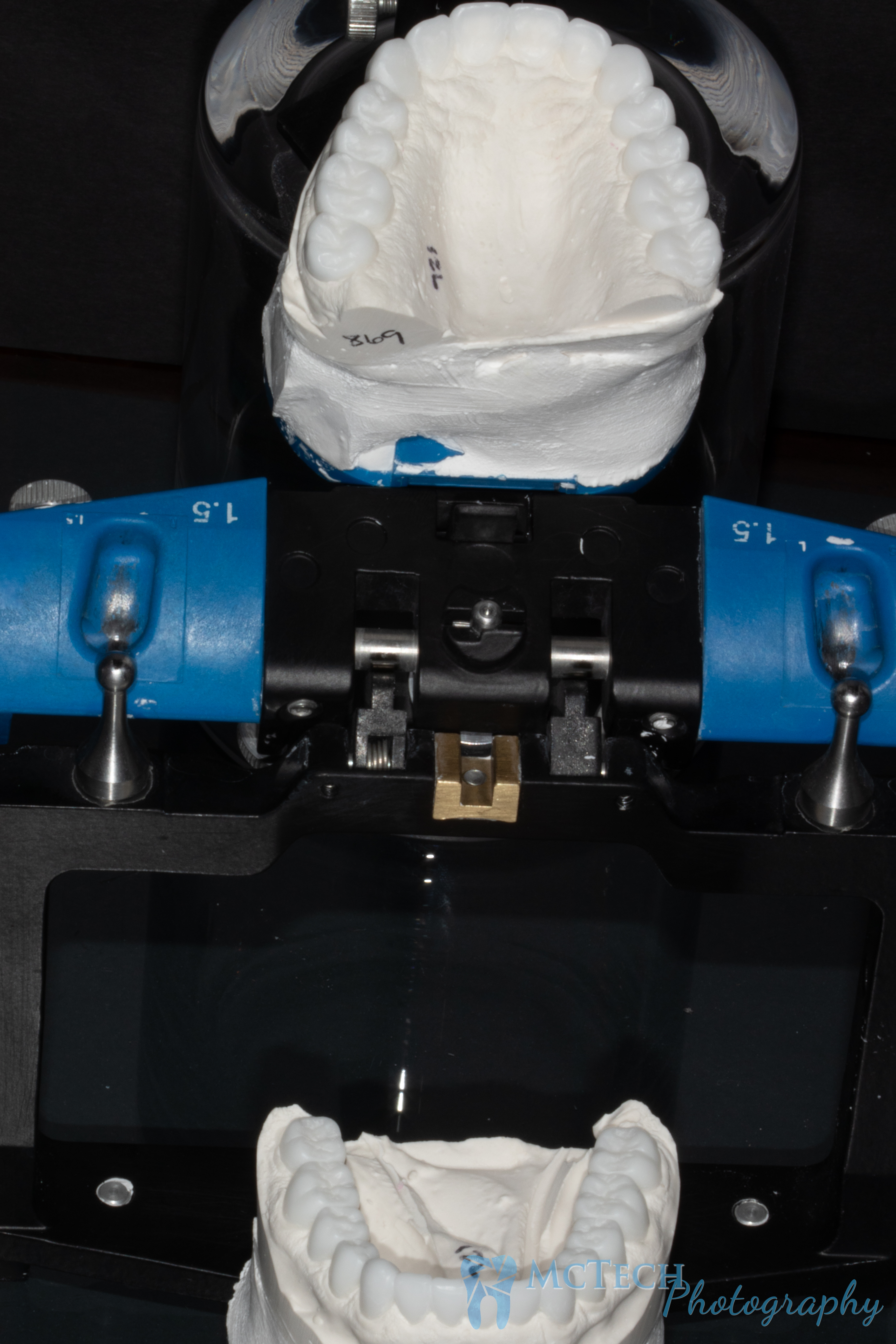

contour restorations, Mark McKee CDT, McTechs founder and head technician can give this technology a real run for its money. Especially if both are starting with stone model work, Mark can hand wax a posterior crown and have it casting or pressing before the mill is done. So what? What else does that crown mark made have over the CAD designed version? In a word, intimacy. We still train our technicians through the PTC hand wax module, if for no other reason than it gives them an intimate relationship with teeth, with the anatomy, with every cusp and ridge and faucae, along with the various ways a bite is functioning or not functioning. Mark can in the middle of waxing his crown realize through tactile feel and experience that the model room may have missed the bite slightly; he knows what occlusal anomalies to look for that can throw things off. Mark has the experience and expertise to think critically when working with the information given and does not just assume it is correct. Technicians born and raised in CAD, and yes even AI, are handicapped when it comes to these and many other functions. This means even the most straightforward case can suffer from operator ineptitude and the most advanced AI in the world can still only work with the information given. Complex jaw movements like those seen when speaking or dynamic mastication movements rarely if ever make it into the design of a sole CAD CAM restoration, even one made by a seasoned technician. While it is easy enough to add vertical space between teeth and even use a virtual articulator to estimate the final positions, it still requires at the very least a physical  model on an appropriate articulator to perform the actual movements. There is however new technology such as Modjaw that can not only bring in these complex movements but even individualize them to the specific patient and allow the CAD technician to incorporate them into restorations. At which point we can finally have a crown that once milled, still needs to be glazed and fitted to articulated model work. For now, Mark and the rest of McTech Technicians incorporate excursive protrusive and other movements whenever we can, to eliminate interference, even on quadrant models.

model on an appropriate articulator to perform the actual movements. There is however new technology such as Modjaw that can not only bring in these complex movements but even individualize them to the specific patient and allow the CAD technician to incorporate them into restorations. At which point we can finally have a crown that once milled, still needs to be glazed and fitted to articulated model work. For now, Mark and the rest of McTech Technicians incorporate excursive protrusive and other movements whenever we can, to eliminate interference, even on quadrant models.

Margins must seal, proximal contacts must be broad and tight and without food traps, and occlusion must function. The degree of precision achieved is determined during seating and presumes a precise condition of the oral situation was given and has not changed. Obviously in the real-world teeth drift or erupt and margins can chip for various reasons. Regardless of if a crown is milled or hand waxed it will be evaluated on this metric.

Intra oral Scanning cannot be ignored as a factor when it comes to accuracy. According to Marks experience and some actual blind tests McTech conducted, a properly taken PVS impression will still yield greater details and sometimes those details can mean the difference between a sealed margin or high contacts. This is for many reasons that deserves its own blog altogether to rightly explain and it must be noted traditional impressions are not without variables. Because We are not in control of whether a doctor sends us a traditional of digital impression, and for the purposes of this article, we will not focus on this aspect of the CAD CAM workflow.

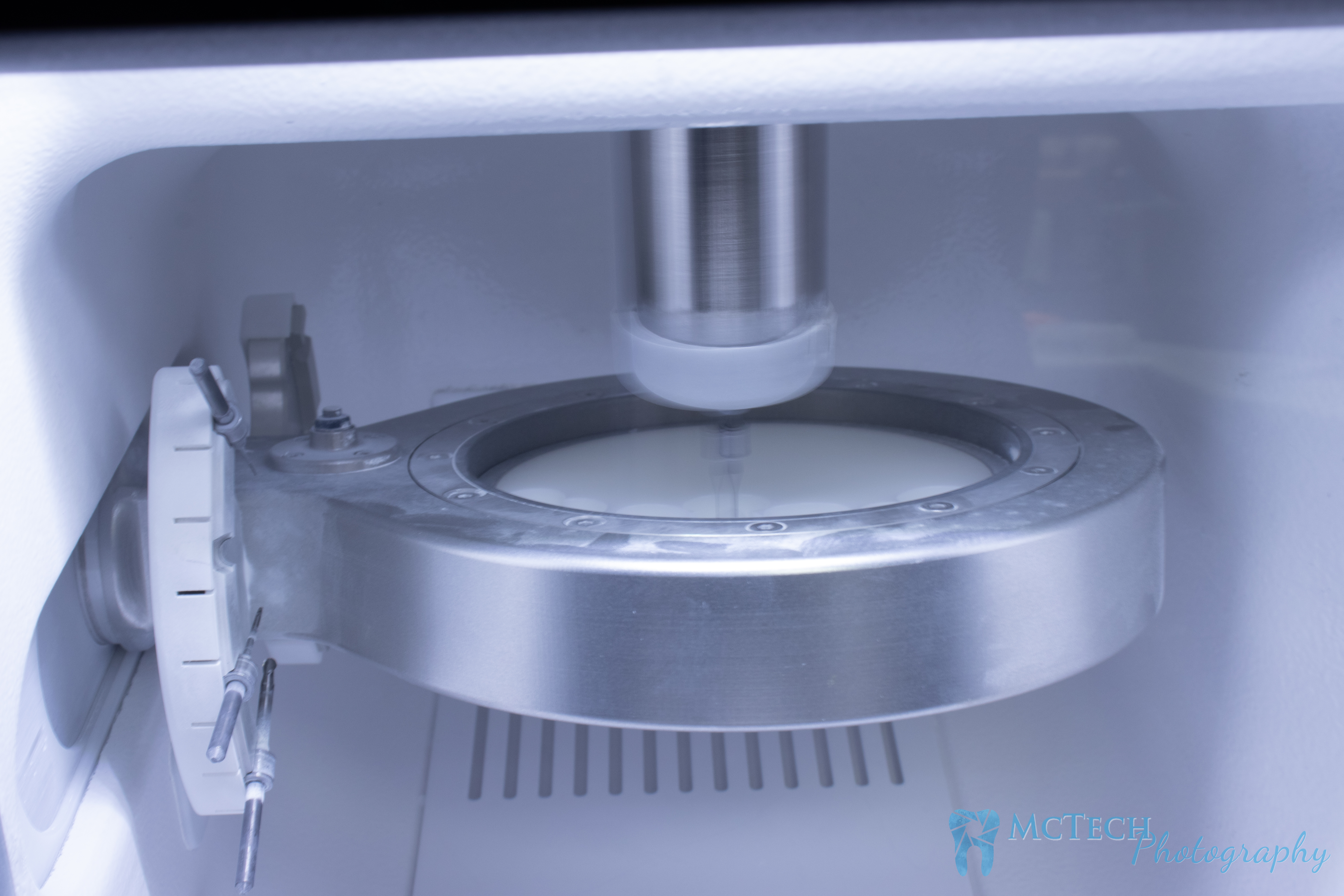

Which means the question of accuracy really falls on the second half of CAD CAM, Computer Aided Manufacturing, specifically milling. The question is refined to “how fine of detail can one achieve when milling a digitally designed restoration vs. Hand waxing it”. In a mill, one needs to consider several factors with just the bur alone. How small is the smallest bur used? On what features is that smallest bur used? Is the smallest bur grinding or cutting? how sharp is that smallest burr from one mill to the next? Next to consider is the tool path. To which must be considered the hardware. How many axis and what is the speed and capability of the spindle? All these variables in precision are compounded greatly by the material being milled. A short list of possibilities includes titanium, pre-sintered lithium disilicate, PMMA, pre-sintered zirconia or wax. Obviously, these very different materials can present very different challenges in tolerances for heat and pressure and spindle speed and how they heat up, or gum up that smallest bur. The result depends on a myriad of factors. for some materials that smallest bur is getting larger and larger, which means precision is suffering more and more. This is a gross summation, but the good news is with proper maintenance and calibration of your mill, using reputable and knowable qualities of materials, and with the right hardware and software support, a mill can automate all

Which means the question of accuracy really falls on the second half of CAD CAM, Computer Aided Manufacturing, specifically milling. The question is refined to “how fine of detail can one achieve when milling a digitally designed restoration vs. Hand waxing it”. In a mill, one needs to consider several factors with just the bur alone. How small is the smallest bur used? On what features is that smallest bur used? Is the smallest bur grinding or cutting? how sharp is that smallest burr from one mill to the next? Next to consider is the tool path. To which must be considered the hardware. How many axis and what is the speed and capability of the spindle? All these variables in precision are compounded greatly by the material being milled. A short list of possibilities includes titanium, pre-sintered lithium disilicate, PMMA, pre-sintered zirconia or wax. Obviously, these very different materials can present very different challenges in tolerances for heat and pressure and spindle speed and how they heat up, or gum up that smallest bur. The result depends on a myriad of factors. for some materials that smallest bur is getting larger and larger, which means precision is suffering more and more. This is a gross summation, but the good news is with proper maintenance and calibration of your mill, using reputable and knowable qualities of materials, and with the right hardware and software support, a mill can automate all .jpg) these variables into a consistent reliable result. A result that will still only be as finely detailed as the smallest bur used allows. It is the consistency in the face of all these seemingly insurmountable variables that lend to CAMs true advantage, consistency, not necessarily precision. Compare that to hand wax and the exact opposite is true. Consistency is at the mercy of a human but what is gained is truly microscopic potential in detail. When hot wax is on a surface, it achieves an accuracy as fine and detailed as the surface on which it is run. There is no complex mathematics to wax, and the lost wax technique has been through centuries of scientific research and development. Variables of expansion and contraction of the investment and final materials have been rigorously evaluated and accommodated for. When pressing Lithium disilicate, or casting gold, a sharpness of detail can be produced that can even replicate the doctors bur tracks next to the margin

these variables into a consistent reliable result. A result that will still only be as finely detailed as the smallest bur used allows. It is the consistency in the face of all these seemingly insurmountable variables that lend to CAMs true advantage, consistency, not necessarily precision. Compare that to hand wax and the exact opposite is true. Consistency is at the mercy of a human but what is gained is truly microscopic potential in detail. When hot wax is on a surface, it achieves an accuracy as fine and detailed as the surface on which it is run. There is no complex mathematics to wax, and the lost wax technique has been through centuries of scientific research and development. Variables of expansion and contraction of the investment and final materials have been rigorously evaluated and accommodated for. When pressing Lithium disilicate, or casting gold, a sharpness of detail can be produced that can even replicate the doctors bur tracks next to the margin of a prep and creates a truly seamless margin seal. Gold especially is a centuries old material that still has relevance for some patients. McTech has experimented with both milling companies in the states who offer a gold crown milled from a CAD File. It is the same story as with milled lithium disilicate. The detail is still lost, the bur can only be so small, so that’s not a better crown.

of a prep and creates a truly seamless margin seal. Gold especially is a centuries old material that still has relevance for some patients. McTech has experimented with both milling companies in the states who offer a gold crown milled from a CAD File. It is the same story as with milled lithium disilicate. The detail is still lost, the bur can only be so small, so that’s not a better crown.

This brings us to our conclusion as to why we incorporate a mix of both CAD CAM and traditional methods into our workflow. Here is a short list as it relates to what we’ve covered so far.

We 3D print model work for every case sent digitally and pour stone up for every case sent with an impression. We confirm every bite by hand when possible. Every case is worked through dynamic jaw movements when finishing and we see in our hands what the crown looks like with the other teeth. We do not do modeless, not because we are not capable, but because it is a disservice to the patient not to have the information available to you at the seating appointment regarding the fit of the margin and contacts, the line of draw, and so you can see in your hands the information sent us to work with.

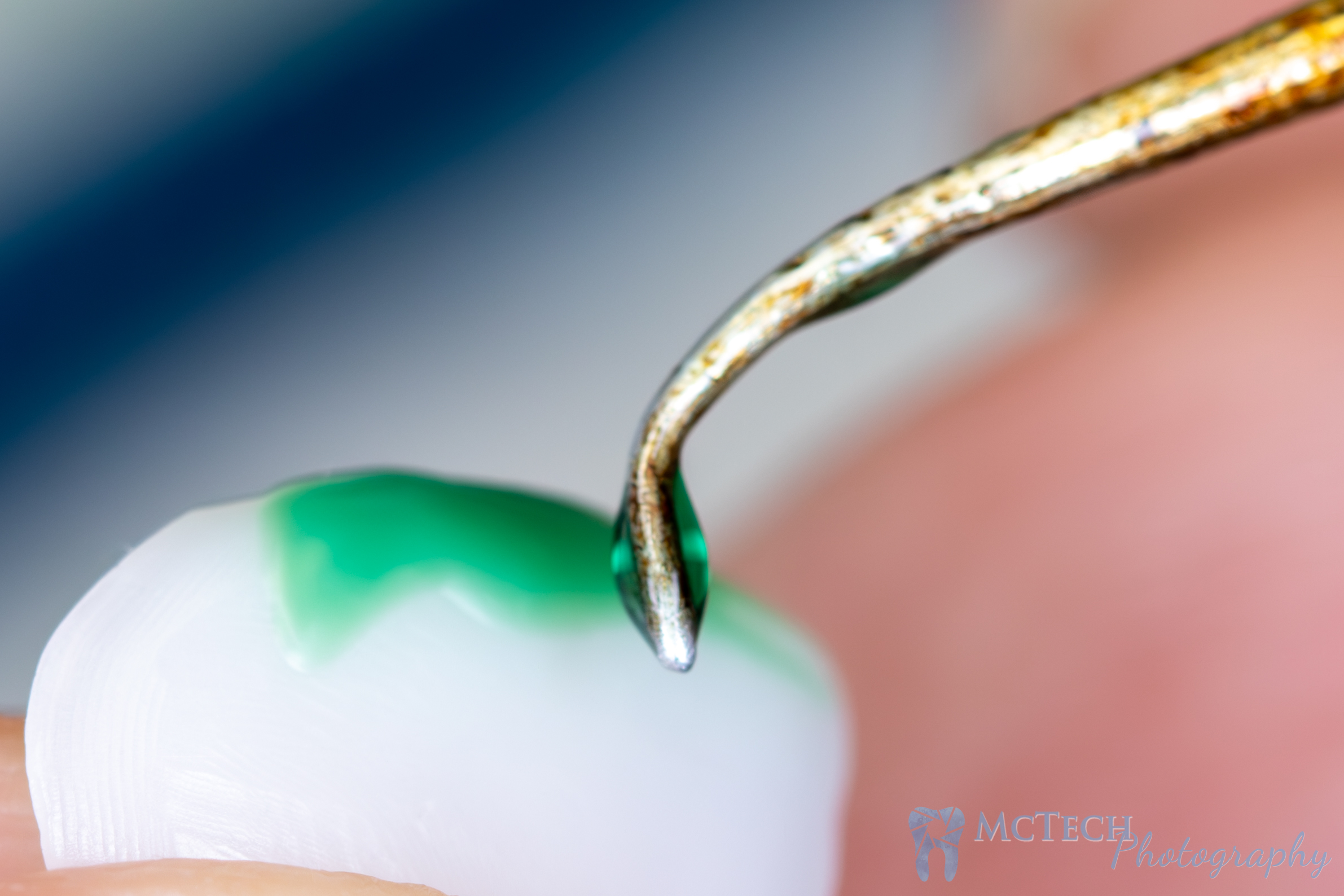

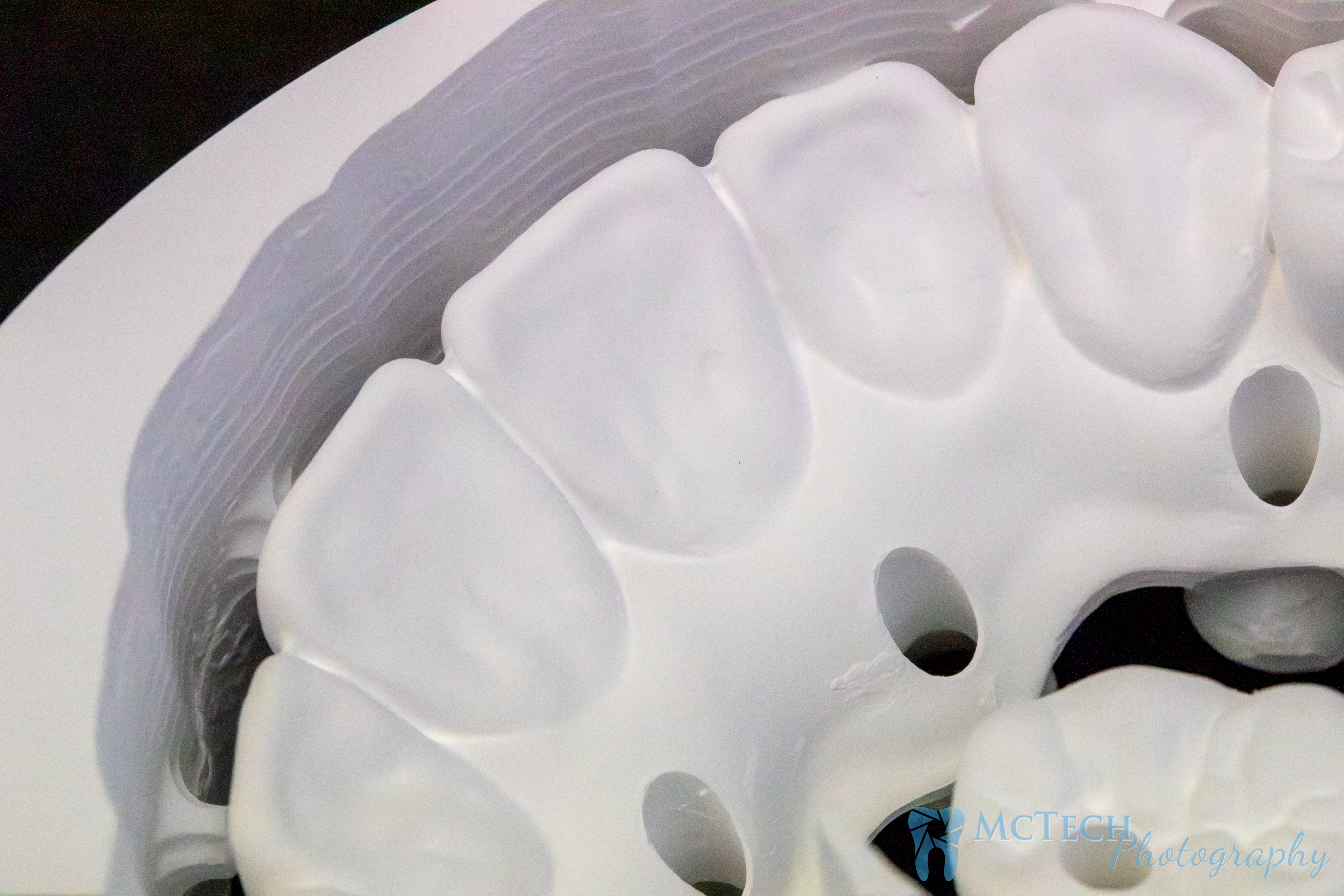

We 3D print model work for every case sent digitally and pour stone up for every case sent with an impression. We confirm every bite by hand when possible. Every case is worked through dynamic jaw movements when finishing and we see in our hands what the crown looks like with the other teeth. We do not do modeless, not because we are not capable, but because it is a disservice to the patient not to have the information available to you at the seating appointment regarding the fit of the margin and contacts, the line of draw, and so you can see in your hands the information sent us to work with. We combine the best worlds of CAD CAM and accept none of the compromises. To that end we mill all gold and e.max crowns out of a wax puck, then finish, confirm occlusion, touch up contacts and margins with a hot wax wand before pressing or casting. We keep the wax wand in hand to add our art and individuality to the aesthetics of every case.

We combine the best worlds of CAD CAM and accept none of the compromises. To that end we mill all gold and e.max crowns out of a wax puck, then finish, confirm occlusion, touch up contacts and margins with a hot wax wand before pressing or casting. We keep the wax wand in hand to add our art and individuality to the aesthetics of every case.- We hand wax all metal frameworks, it’s faster, more precise, and we’ve been doing it this way for more than 30 years.

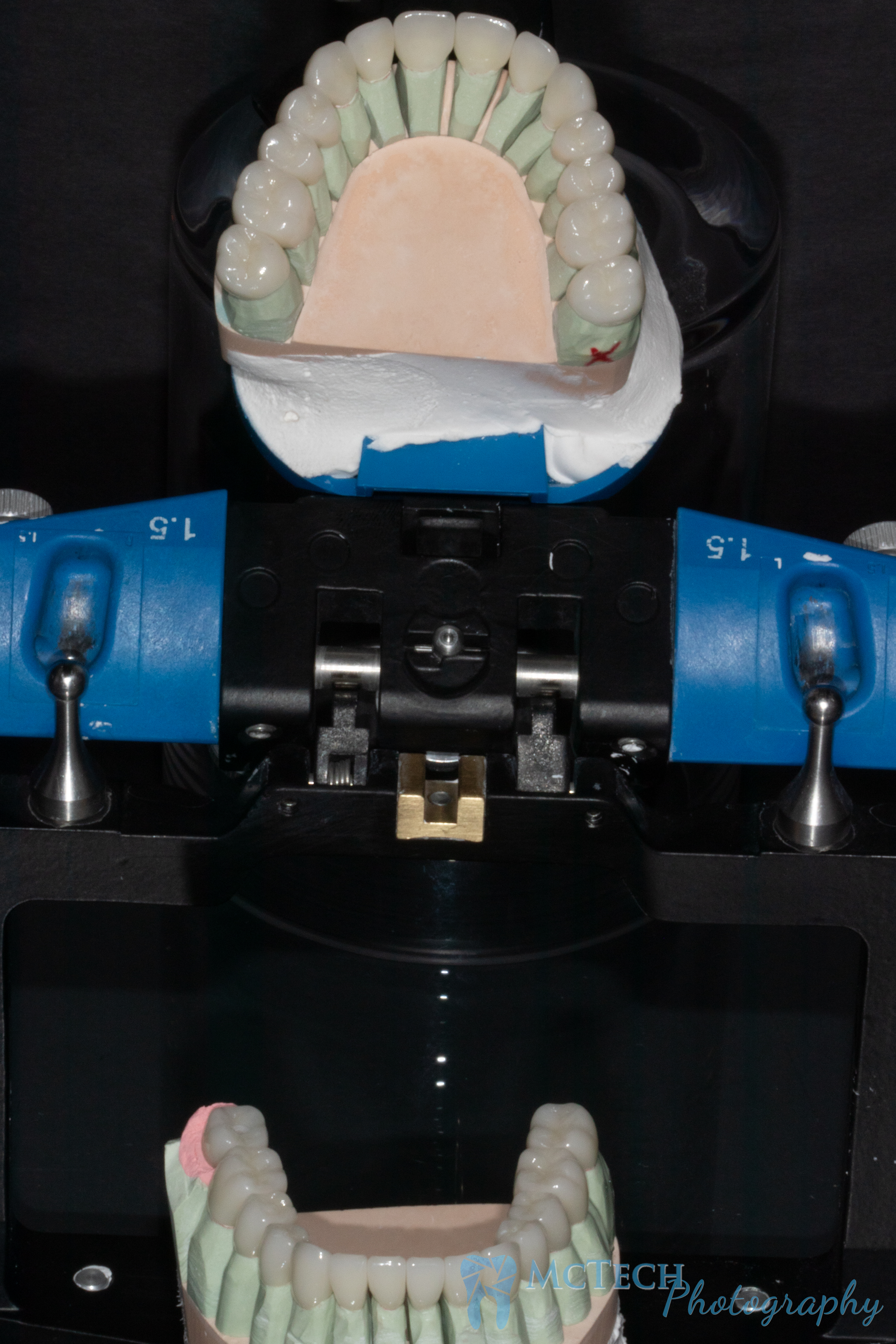

If you’ve been paying attention, you are no doubt asking why does Zirconia gets a pass on all this? Zirconia is a material worthy of a blog all itself but for the relevance of this article just a few notes. Zirconia was borne from the CAD CAM workflow, you can’t hand wax a zirconia crown, making a comparison moot. Zirconia greatly benefits from using 3D printed model work for application of color, glaze, and confirm fit and slightly adjust for complex jaw movements. The nature of the material itself makes big changes and adjustments difficult and can even compromise its integrity, making it important to get it as right in CAD as possible. This is where milling other materials in wax comes in handy. We mill in white wax and touch up in green wax. Through close collaboration between technicians over time, we have used less and less green wax. This  translates into fewer and fewer zirconia touchups as well. Zirconia is a modern material that requires a modern workflow, but we still find ways to incorporate our art into it. To that end, McTech utilizes a liquid ceramic called MIYO to add our art and individuality to the aesthetics. As to the precision of the mill, pre-sintered zirconia has a hardness and consistency like chalk. This makes it much easier on the burs than pre-sintered lithium disilicate or metal with great heat dispersal and no gumming. This means the smallest bur we can use is very small. Adding to that, once the zirconia is sintered it shrinks 20%, meaning the .03mm burr in our Amman Girbach mill is milling a margin 20% larger than the real thing and all those occlusal details are going to be there in even sharper clarity after sintering. Look forward to more on this topic in a later blog.

translates into fewer and fewer zirconia touchups as well. Zirconia is a modern material that requires a modern workflow, but we still find ways to incorporate our art into it. To that end, McTech utilizes a liquid ceramic called MIYO to add our art and individuality to the aesthetics. As to the precision of the mill, pre-sintered zirconia has a hardness and consistency like chalk. This makes it much easier on the burs than pre-sintered lithium disilicate or metal with great heat dispersal and no gumming. This means the smallest bur we can use is very small. Adding to that, once the zirconia is sintered it shrinks 20%, meaning the .03mm burr in our Amman Girbach mill is milling a margin 20% larger than the real thing and all those occlusal details are going to be there in even sharper clarity after sintering. Look forward to more on this topic in a later blog.

McTech is confident in its ability to compete in the market despite these revelations in its manufacturing process. We consider it an obligation to communicate that traditional materials benefit greatly from a well-formulated mix of modern and traditional techniques. As dental technicians, we consider ourselves to be highly skilled specialists and members of a team. This kind of transparency into our materials and methods helps our doctors to guide the patients best interest with enlightened reasoning, to understand the wisdom in valuing quality dentistry over convenience.

We look at every restoration we create as an extension of a human body, designed to restore quality of life through its function and dignity through its aesthetics. The most complex cases are when the patient presents with disfunction so severe that a complete rehabilitation of occlusion and design is necessary. In an industry obsessed with full arch all-on-x restorations, McTech finds an example of precision as still being able to work with the old school conservative dentist by nailing that 28 single unit full mouth rehabilitation with little to no adjustments and perfect margin seals. When our doctors put in the extra effort on that prep appointment, they feel great when an 8-hour seating appointment gets cut in half. And so does the patient, who’s retelling the experience then goes on to grow the doctors and by extension the lab’s reputation. That is precision, that is profitable, without compromise.